On the planet of electronics, the importance of PCB assembly can not be overstated. As gadgets end up being small and progressively complicated, the demand for premium PCB assembly producers has surged. Printed Circuit Boards, or PCBs, work as the foundation of a lot of digital tools, providing a system for the connection and capability of numerous electronic elements. When discussing PCB assembly, it is crucial to comprehend not only the procedures involved yet likewise just how to select the most effective PCB assembly manufacturer to make sure that the last product fulfills the greatest criteria of quality and dependability.

The PCB assembly process consists of a number of crucial steps, consisting of assembly, design, and prototyping. Creating a PCB involves creating a schematic representation that details just how the numerous components will connect with each other.

One necessary facet of PCB assembly is surface area place technology (SMT), a method that has revolutionized the manufacturing process by enabling the placing of components straight onto the surface area of the PCB. This strategy has made best use of room efficiency and permitted more complex circuit designs. Another usual approach is through-hole modern technology, where parts are inserted right into openings on the PCB and soldered in position. Each approach has its applications, advantages, and downsides, and frequently, suppliers will certainly employ a mix of both to achieve the preferred assembly outcomes.

When selecting a PCB assembly manufacturer, numerous aspects should be considered to ensure the very best possible outcome. Among the most vital requirements is the manufacturer's experience and reputation in the sector. A respectable manufacturer should have a tried and tested record of providing top quality items and outstanding customer support. Testimonials and testimonials from previous clients can be important in assessing the dependability of a manufacturer. In addition, qualifications such as ISO 9001 or IPC requirements can provide more recognition of adherence to quality administration practices.

The best PCB assembly suppliers remain at the leading edge of technology, supplying innovative production procedures and equipment. The latest equipment can substantially improve the precision and rate of PCB assembly, inevitably guaranteeing a higher top quality end product.

Price is an additional essential consideration when selecting a PCB assembly manufacturer. While the rate is a necessary factor, it must not be the single factor. An affordable price usually comes with the cost of quality, which can lead to a host of concerns in the future. It is important to get quotes from several producers and compare not simply the rates however also what is consisted of in each quote. This can supply clarity regarding where the worth exists.

It is crucial to talk about timelines ahead of time and have a clear understanding of the manufacturer's capacity to satisfy deadlines. Delays in assembly can have plunging results on product launches and supply chain administration, which can inevitably impact a business's success.

As soon as an ideal PCB assembly manufacturer has been selected, the partnership should begin with open communication. Producers that are prepared to work carefully with clients to fix problems or make enhancements demonstrate a reputable collaboration.

Quality control measures need to be in location from the early phases of assembly, consisting of evaluations, testing, and confirmation processes. Making use of automated optical evaluation (AOI) can help capture defects that might not be visible to the nude eye, while functional screening can confirm that the constructed PCB carries out properly in real-world problems.

Trends such as miniaturization, enhanced intricacy, and the demand for customization are driving advancements in PCB layout and assembly procedures. Staying upgraded on these growths permits a business to choose a PCB assembly manufacturer that does not just meet present requirements yet is additionally prepared for future demands.

Sustainability is becoming a progressively crucial element of electronic devices making. As companies and consumers alike end up being much more environmentally conscious, dealing with a PCB assembly manufacturer that prioritizes environmentally friendly processes can improve your brand's track record. This can consist of the usage of lead-free solder, reusing programs, and accountable waste administration methods.

One more essential consideration when talking about PCB assembly is the capacity for recurring assistance and service after the assembly is complete. A quality manufacturer does not simply deliver the constructed PCB and walk away; they must be readily pcb assembly available for assistance with any issues that may occur post-delivery. Whether it's repairing, fixings, or upgrades, having actually a trusted partner that can give continuous support can be indispensable in maintaining the longevity and efficiency of electronic products.

Looking in advance, welcoming technical improvements and promoting solid relationships with PCB assembly suppliers will be key to doing well in the fast-evolving electronics landscape. The merging of emerging modern technologies, consumer assumptions, and sustainability will certainly define the future of PCB assembly.

In verdict, browsing the globe of PCB assembly requires a comprehensive understanding of the manufacturing process, a strategic approach to selecting the best PCB assembly manufacturer, and a dedication to top quality and technology. Hence, picking to function with a reputable PCB assembly manufacturer is not just a technological choice; it is a tactical business selection that can move a brand in the direction of long-lasting success.

Jake Lloyd Then & Now!

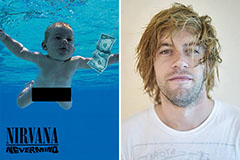

Jake Lloyd Then & Now! Spencer Elden Then & Now!

Spencer Elden Then & Now! Kirk Cameron Then & Now!

Kirk Cameron Then & Now! Bug Hall Then & Now!

Bug Hall Then & Now! Tonya Harding Then & Now!

Tonya Harding Then & Now!